BOIRON RELIABILITY

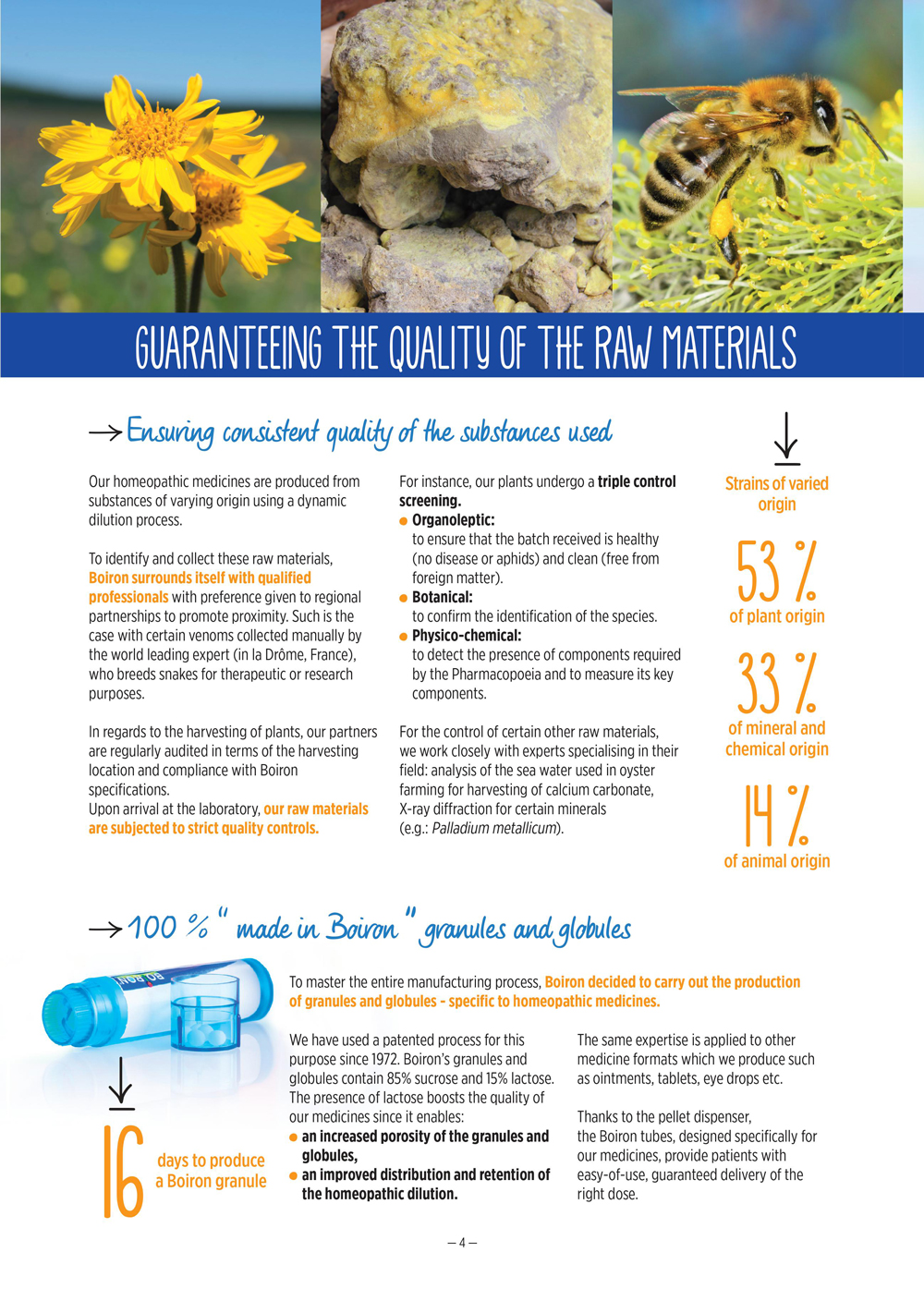

Guaranteeing the quality of the raw materials

Ensuring consistent quality of the substances used

Our homeopathic products are produced from substances of varying origin using a dynamic dilution process.

To identify and collect these raw materials, Boiron surrounds itself with qualified professionals with preference given to regional partnerships to promote proximity. Such is the case with certain venoms collected manually by the world leading expert (in la Drôme, France), who breeds snakes for therapeutic or research purposes.

In regards to the harvesting of plants, our partners are regularly audited in terms of the harvesting location and compliance with Boiron specifications. Upon arrival at the laboratory, our raw materials are subjected to strict quality controls. For instance, our plants undergo a triple control screening.

- Organoleptic: to ensure that the batch received is healthy (no disease or aphids) and clean (free from foreign matter).

- Botanical: to confirm the identification of the species.

- Physico-chemical: to detect the presence of components required by the Pharmacopoeia and to measure its key components.

For the control of certain other raw materials, we work closely with experts specialising in their field: analysis of the sea water used in oyster farming for harvesting of calcium carbonate, X-ray diffraction for certain minerals.

100 % “ made in Boiron ” granules and globules

To master the entire manufacturing process, Boiron decided to carry out the production of granules and globules - specific to homeopathic products.

We have used a patented process for this purpose since 1972. Boiron’s granules and globules contain 85% sucrose and 15% lactose. The presence of lactose boosts the quality of our products since it enables:

- an increased porosity of the granules and globules,

- an improved distribution and retention of the homeopathic dilution.

The same expertise is applied to other products formats which we produce such as cream, unidose, ointments, tablets, eye drops etc.

Thanks to the pellet dispenser, the Boiron tubes, designed specifically for our products, provide patients with easy-of-use, guaranteed delivery of the right dose.

MASTERING THE SPECIFIC FEATURES OF A UNIQUE PRODUCT

Triple medication: a Boiron innovation that became a standard procedure

In 1961, Jean Boiron developed and patented a triple medication process guaranteeing homogeneous medication of the active ingredient down to the core of the granule.

Originally carried out by hand, triple medication has now become standardised to guarantee the quality of the various stages:

- Micro-spraying using glass nozzles calibrated to the nearest micron,

- Homogenisation optimised by controlling the angle of inclination and rotation speed of the turbines,

- Filtered Air drying

Automated succussion to guarantee reproducibility

Succussion, a vital step in the preparation of homeopathic dilutions, is carried out mechanically, using a specialised machine called a “succussor.” This process guarantees reproducibility in terms of frequency, duration and amplitude of the succussing: succussed 150 times over 7 seconds. This ensures that the succussion is perfectly identical from one dilution to the next.

Innovation serving tradition

A MORDENIZED MANUFACTURING faithful to traditional processes

Ever since our inception, our mission has been to improve technical manufacturing conditions to ensure the large-scale production of a reproducible and reliable homeopathic product. Our teams work on a daily basis to strike a balance between respect for traditional procedures and constant technological innovation.

To achieve this, we have developed our own industrial tool, designed specifically to respond to the unique manufacturing process adopted for homeopathic products: e.g. succussion, triple medication, granules and globules manufactured onsite. This industrial process ensures that our products are perfectly reproducible with the same quality of product available across the world.

Quality control: a constant requirement

Within our teams, over 60 staff members focus on quality control across the manufacturing process. We have our own specialised laboratories.

- Chemistry laboratory: Approximately 4,000 analyses each year: liquid chromatography, gas chromatography, (UV and IR) spectrophotometry, atomic absorption spectrometry, etc.

- Bacteriology laboratory: Around 23,000 control procedures are performed each year on raw materials.

- Botanical laboratory: Over 3,000 controls are carried out every year, from receipt onwards, by a team of pharmacists, chemists and botanists. The Boiron production sites are regularly inspected by the French National Agency for Medicines and Health Products Safety (ANSM).

We are also audited by the authorities in countries where our products are available:

recently Brazil (ANVISA, Agência Nacional de Vigilância Sanitária, in 2011), the United States (FDA, Food and Drug Administration, in 2015), Kazakhstan (National Centre for Drug Expertise, in 2014).